Introduction to Laser cutting

v0.5 by Ger Walsh - first uploaded Nov 2023

contributions by a "nervous first time user" (May 2023)

This is a guide to Laser Cutting and Engraving - this page is a general guide - though we will have specific examples from the Trotec Speedy400 and from the Lasersaur (developed by Lasersaur.org), which are both machines available for public use at Fab Lab Limerick.

Sections

Background

This diagram is a CO2 bulb made of glass, which is not what the Trotec uses.

A Laser Cutter is a machine for engraving and cutting material. A laser beam is produced by a particular source, for instance, a Carbon Dioxide bulb or, in some cases, directly from a diode. LASER is an acronym for Light Amplified by the Stimulation of Electronic Radiation, which is a potential hazard of laser cutting machines.

This guide is for the Trotec Speedy400, a professional 80 watt CO2 machine, with many features that offer a high-quality finish, including processing raster engravings, and optional attachments like automatic material loaders, rotary tools for glassware etc. and definitions up to 1000 dpi.

...but hopefully the information will be general enough to be relevant to other laser cutters too.

So, let's have a sneak-peek...

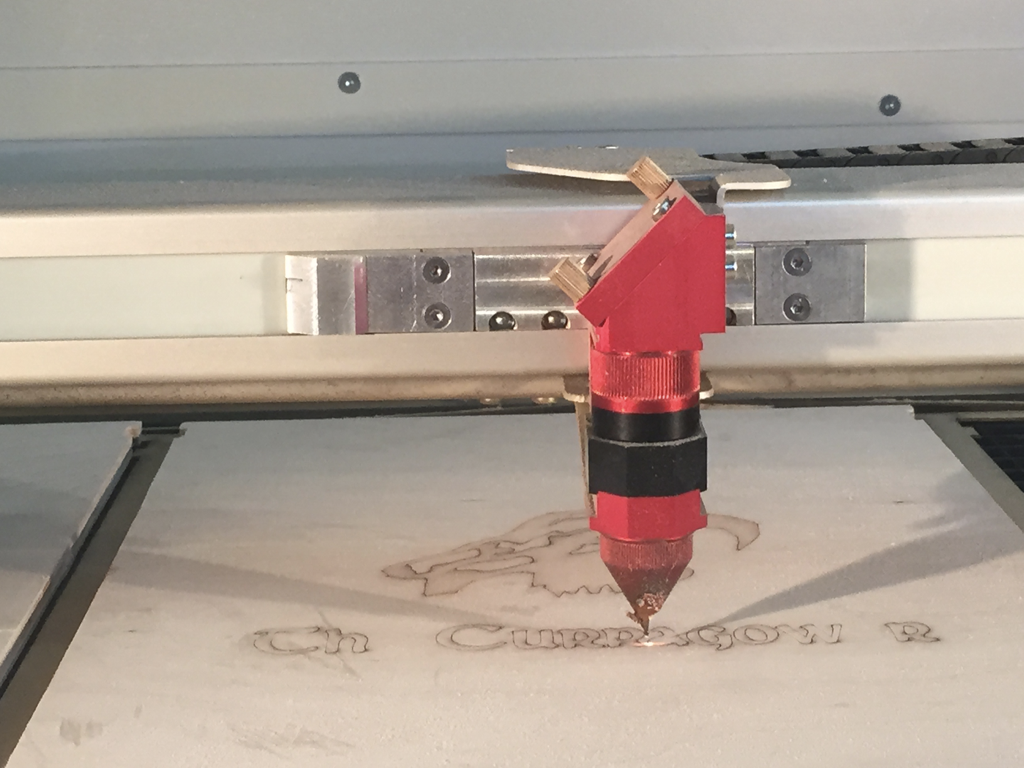

Raster Engraving - Flex Laser

Vector Cutting - CO2 Laser Cutter

Health & Safety

Before using a laser cutter, note your safe operating procedure, where any emergency stop buttons are, where Fire extinguisher is placed and the steps of your fire emergency procedure. Do not leave the laser unattended when it is in operation. And if you notice that any of the panels or wires are loose, contact a staff member. Do not use the machine.

Laser cutters use amplified light to burn materials. The CO2 source emits Class 4 radiation. Laser Cutters have protective shielding and an enclosure for normal use. The machine should not be operated while the cover is open, panels are obstructed, etc.. In the case that one of maintenance, we have special protective goggles that need to be worn.

Direct exposure will cause sight loss.

Each machine has Red e-Stop Switches for emergencies. Note their location before using the machine.

Note the location of the nearby Fire Extinguishers, each of which are safe for electrical fires. There is a Powder Extinguisher (left) and the CO2 Extinguisher at the right. Both can be used for electrical fires; the powder extinguisher is also suitable for chemical fires.

- Use upright.

- Pull out safety pin.

- Free the hose.

- Aim at the base of the fire.

- Squeeze the handles.

Again, please report immediately to staff, any possible issues with the machines and DO NOT operate the machines if you have any doubt.

Please refer to our Health & Safety Page for more information.

Materials

Laser Cutters are extremely versatile machines. Fab Lab Limerick encourages experimentation, but this has to be done safely. Check with the manufacturer, supplier or shop to see if materials are safe. The following is a table from Trotec.

| Engrave/Etch | Cut | |

|---|---|---|

| Acrylics | ✔ | ✔ |

| Plastic | ✔ | ✔ |

| Glass | ✔ | ✘ |

| Textiles | ✔ | ✔ |

| Leather | ✔ | ✔ |

| Paper and Card | ✔ | ✔ |

| Wood | ✔ | ✔ |

| Stone | ✔ | ✘ |

| Metal* | ✘ | ✘ |

In most materials, the Trotec can cut up to 6mm only; the Lasersaur a little less.

*CO2 lasercutters cannot cut Metals, Stone or Glass. However, Stone and Glass can be engraved.

**Certain plastics are to be cautious of. Cutting PVC releases Chlorine gas, which is highly toxic. Fumes will damage machine parts and can kill. PVC is a common consituent of plastic products, particularly where durability, water- or weatherproofing is important. For example Pleather.

Some other plastics(list from troteclaser.com): Cast acrylic, PES film, PE foam, LaserFlex, ABS, extruded acrylic, polyamide (PA), polybutylene terephthalate (PBT), polycarbonate (PC), polyethylene (PE), polyethylene terephthalate (PET), polyimide (PI), polyoxymethylene (POM) - i.e. Delrin, polyphenylene sulfide (PPS), polypropylene (PP), polystyrene (PS), polyurethane (PU, PUR).

Polycarbonate doesn't cut well beyond 1mm thickness. Likely owing to the wavelength not matching. Same is possibly true for Delrin (not confirmed)

It may be difficult to get details about particular plastic. If you can a manufacturer Safety Data Sheet (SDS) is ideal. Try to find out from the supplier or shop.

The RIC symbol is also a grea way to help identify a plastic.

There are tests that you may find online to narrow down the type of plastic. Do not attempt these unless you are aware of all the risks and take all appropriate precautions.

Inspiration

](make-laser-cut-maps.png) MAKE Magazine: How To Make Laser Cut Maps Of Your City

MAKE Magazine: How To Make Laser Cut Maps Of Your City

By the way, an Artist in Galway, Thinline.ie, uses laser cutting to make fantastic contoured Irish Coastal Maps.

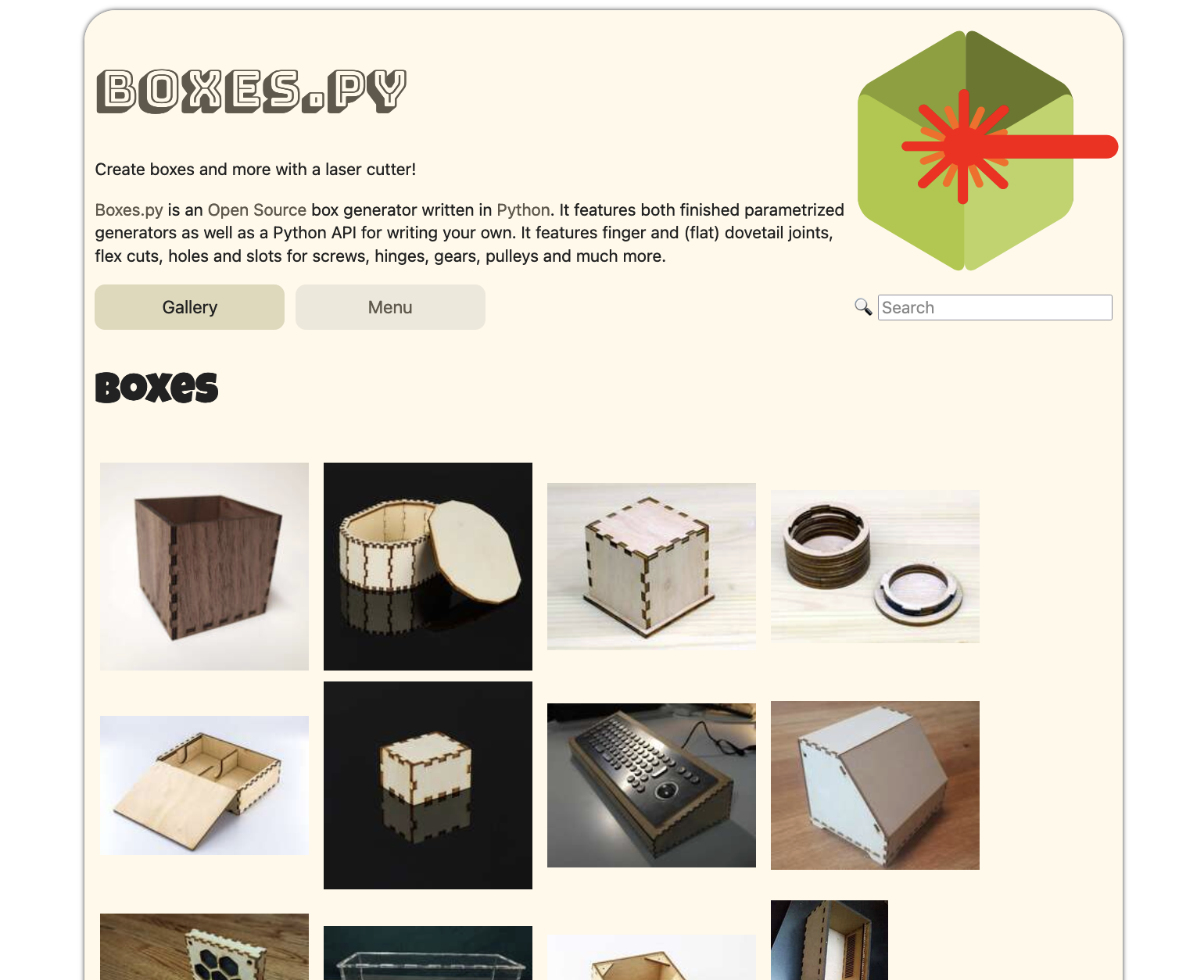

Boxes.py is an online box generator (also an Inkscape plug-in, Python library).

Boxes.py is an Open Source box generator written in Python. It features both finished parametrized generators as well as a Python API for writing your own. It features finger and (flat) dovetail joints, flex cuts, holes and slots for screws, hinges, gears, pulleys and much more.

* Be careful googling, they do not own the Py domain, so search it as separate words or bookmark the link above.

Other Resources

Software:

- Adobe Illustrator (Professional Graphic Design Package, Paid)

- Inkscape (Open source, FREE)

- Affinity Designer 2 (Professional Graphic Design Package, Desktop and iPad, Paid)

- Linearity (iPad, limited files in free version)

- Lightburn ($99 lifetime license)

Paper Craft, and other model making:

- Pepakura Designer($49) or PaperMaker(Free, in-browser)

- Slicer For Fusion360

- LuBan3D (variety of licenses, starting from Free/Unregistered)

On the web:

- Obrary.com

- thingiverse.com (though generally for 3D printing, you can specify "Laser" in your search)

- Boxes.py - Box Generator

Next Steps

Now, for the next steps, go to the Ruby page, or the Preparing Drawings for Ruby page.

Note: Our previous guides for Preparing Drawings and Setting up the Trotec(JobControl) are still available for reference. If you've some function that requires JobControl, we would be happy to switch the machine back.