3D Printing

v0.5 by Ger Walsh - Mar 2025

Introduction

"3D Printing" is a broad collection of technologies, illustrated by the graphic below made by 3Dhubs.com. It describes Additive Manufacturing techniques, adding material to produce a 3D shape from a digital object.

FDM Printing with the Ultimaker 2+

SLA Printing with the Formlabs Form2

SLS Printing with the Sinterit Lisa Pro

- Further Comparison...

(Click here to expand).

(Click here to expand).

3D Printing Comparison Infographic by 3Dhubs.com

| Fused Deposition Modeling (FDM or FFF) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | |

|---|---|---|---|

| Resolution | ★★ | ★★★★★ | ★★★★ |

| Accuracy | ★★★★ | ★★★★★ | ★★★★★ |

| Surface Finish | ★★ | ★★★★ | ★★★★ |

| Throughput | ★★★★ | ★★★★ | ★★★★★ |

| Complex Designs | ★★★ | ★★★★ | ★★★★★ |

| Ease of Use | ★★★★★ | ★★★ | ★★★★ |

| Pros |

|

|

|

| Cons | Low accuracy Low details Limited design compatibility | Sensitive to long exposure to UV light Difficult to remove support material | Rough surface finish Limited material options |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends. | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). | Engineering thermoplastics. Nylon 11, Nylon 12, and their composites. |

This table and further information originally gathered by formlabs.com.

The First 3D Printer

SLA-1, the first 3D printer invented by Chuck Hull in 1983

Chuck Hull invented first 3D printing process, ‘stereolithography’, in 1983. His patent defined stereolithography as ‘a method and apparatus for making solid objects by successively “printing” thin layers of the ultraviolet curable material one on top of the other’.

Though he initially focuses on ‘printing’ with a light-curable liquid, after Hull founded the company ‘3DSystems’, the company expands to other materials, plastics and resins etc.

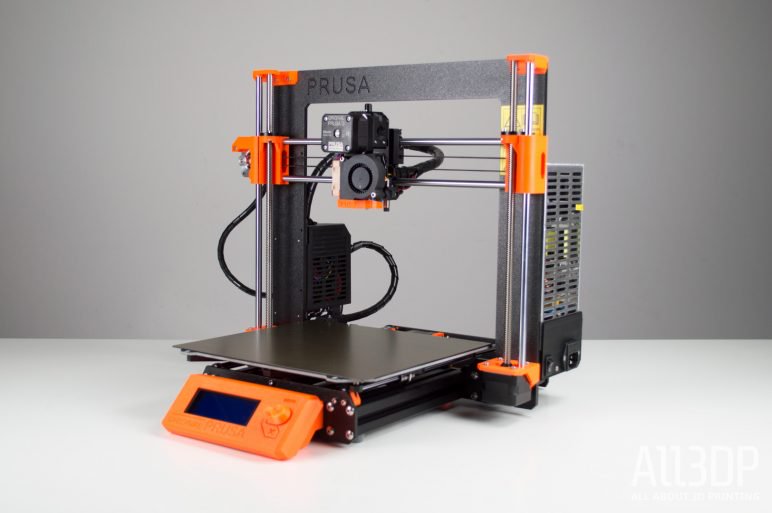

Rep-Rap, the first open source, self-replication 3D printers

Dr Adrian Bowyer interview with Thomas Sanladerer.

Dr Adrian Bowyer, while a Senior Lecturer and a researher in Mechanical Engineering at the University of Bath, UK, founded the Rep-Rap project. A Rep-Rap is an open-source 3D printer that can produce plastic parts, including all such parts for a copy of itself[1].

The project started in England in 2005, from modest message boards and email conversations. Rep-Rap defined many of the tenets of the "3D Printing movement". Rep-Rap produced designs like the Mendel, Huxley and Prusa.

To hear the story from Adrian himself, check out this video interview with Thomas Sanlarderer.

Let's have a closer look...

These printers often made used of 3D printed parts, and were available, firstly, as kits which made them more affordable, and reflected the DIY-origins of Rep-Rap. The decision to embrace the idea of open sourcing their designs, according to Dr Bowyer, came about as a consequence of this.

Next, if you wish, go to the 3D Printing (FDM) page.