3D Printing - SLA (Stereolithography)

v0.1, Ger Walsh - Oct 2022

General

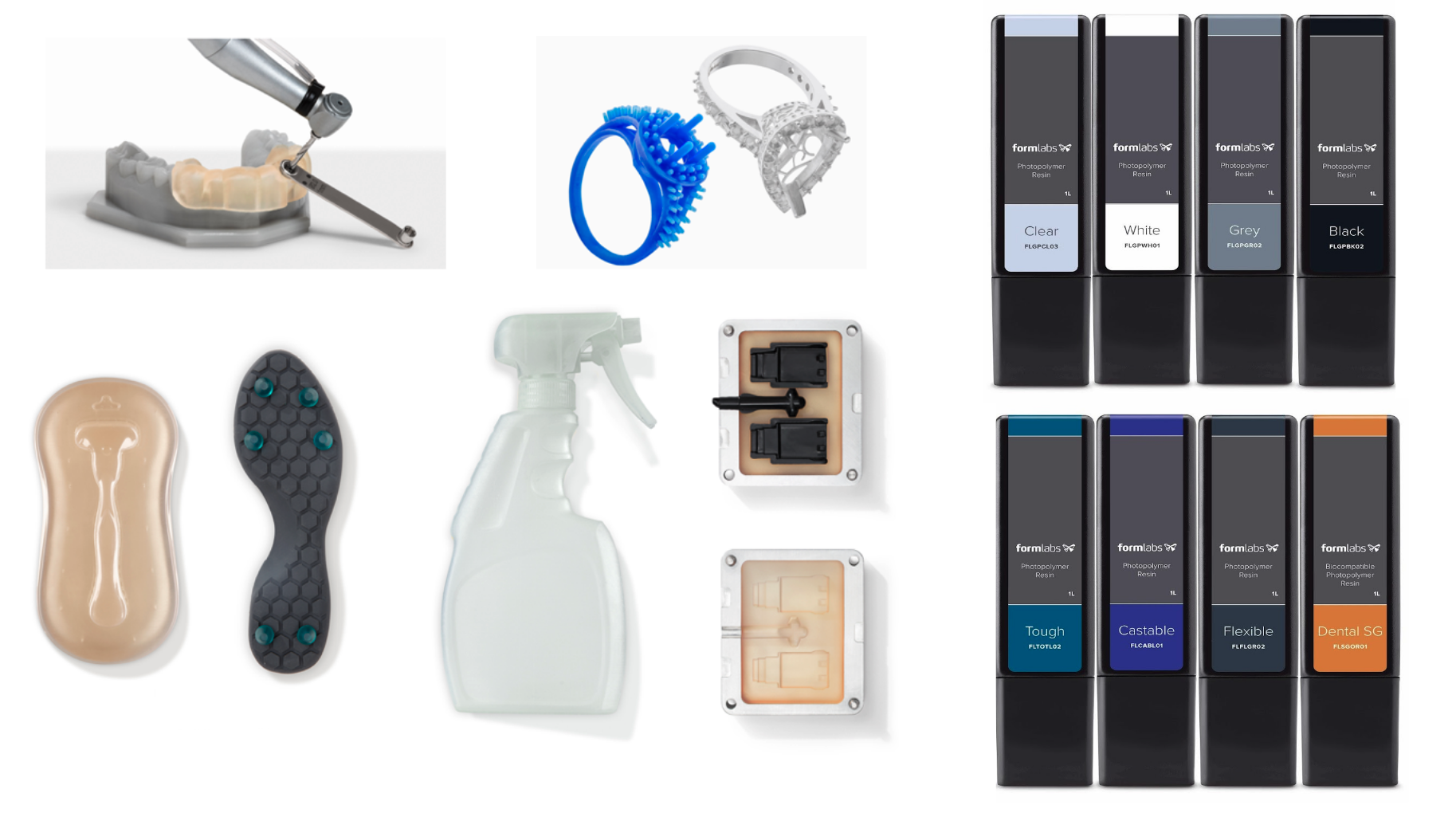

Stereolithography (SLA) Printing is a resin 3D printing process that has become vastly popular for its ability to produce high-accuracy, isotropic, and watertight prototypes and end-use parts in a range of advanced materials with fine features and smooth surface finish.

©Formlabs, The Ultimate Guide to Stereolithography: How SLA Works

Materials

Clear Resin

Stereolithography 3D printing technology makes clear prints possible on the desktop. Clear Resin polishes to near optical transparency, making it ideal for working with light or showcasing internal features.

Ideal for:

- Parts requiring optical transparency

- Optics and lighting

- Fluidics and moldmaking

Flexible Resin

Flexible 80A Resin is the most stiff soft-touch material in our library of Flexible and Elastic Resins, with an 80A Shore durometer to simulate the flexibility of rubber or TPU. Balancing softness with strength, Flexible 80A Resin can withstand bending, flexing, and compression, even through repeated cycles.

Tough Resin

Tough 2000 Resin is the strongest and stiffest material in our functional family of Tough and Durable Resins. Choose Tough 2000 Resin for prototyping strong and sturdy parts that should not bend easily.

- Strong and stiff prototypes

- Jigs and fixtures requiring minimal deflection

- Simulating the strength and stiffness of ABS

Draft Resin

Draft Resin prints up to four times faster than Formlabs standard materials, making it ideal for initial prototypes and rapid iterations to help bring products to market faster. Parts printed with Draft Resin exhibit a smooth grey finish and high accuracy. Use 200 micron settings for fast print speeds, or use 100 micron settings for models with finer details.

- Initial design iterations

- Rapid Prototypes

- High throughput applications

Other materials

New materials are often being developed, including newer versions of existing resins, eg. Castable and Biomed resins. The version number is important when preparing your print. See the full list on the FormLabs website and check with the Fab Lab staff what materials are in stock at the moment.

Design Considerations

Print times are majorly influenced by the number of layers (vertical height of the job), but only minor-ly influenced by the amount of printed material on each layer. Use the PreForm software to test how this works.

Supports: are necessary. The printing happens upside down and support material ensures that material being printed is supported well throughout. PreForm will calculate this automatically for you, but you may edit the position and size of- and add new support connections. Consider the position of support material when orientating your print as removing the supports may leave visible imperfections on the surface. PreForm will also do calculations regarding Local Minima points that will cup and hold liquid resin through the process causing problems later on.

Curing and Washing is an involved process. Always wear protective gloves and work in a well ventilated area when working with resin. Curing is the process where you leave the model in the sun to absorb additional UV light to harden the surface. Instead using a Curing Station, allows you to control the wavelength of light and the length of the exposure more accurately. Washing is done with 99% Isopropyl Alcohol and the cleaning kit available in the lab. Use the flush surface clippers to remove support material as evenly as possible and submerge the model in the washing station for some time to wash uncured resin from the surface. Time for this are experimental. Check with someone in the lab what suits best for your resin and your print.